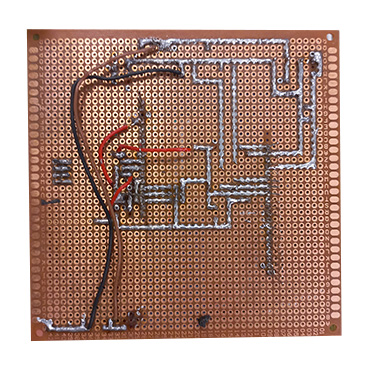

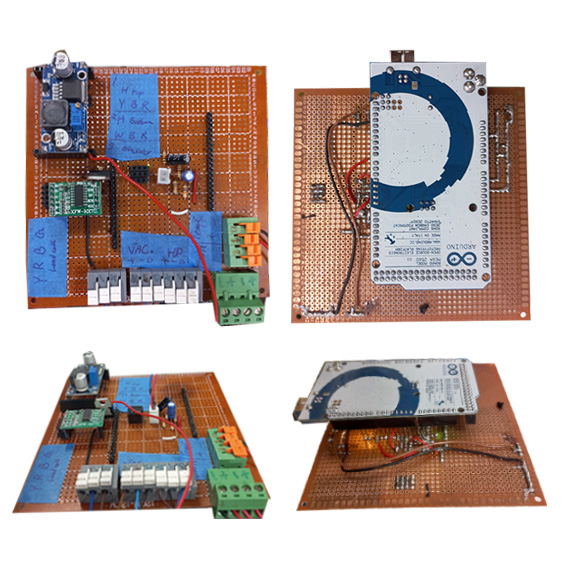

“Understanding the significance of a reliable and cost-effective control board, I took it upon myself to design and fabricate a dedicated stripboard.”

Our endeavor to enhance the Vacuum Assisted Dryer project led us to focus on the crucial aspect of establishing an effective electronic control system. This system was fundamental in monitoring and managing various key variables governing the dryer’s performance. Among these variables were vacuum pressure, inlet pressure, sample temperature, sample weight, chamber humidity, and chamber temperature. To enable precise data acquisition, we carefully selected and integrated appropriate sensors. The sensor feedback played a pivotal role in controlling a Mega Arduino microcontroller, which in turn governed the proportional valve and heaters of the dryer.

This intelligent control mechanism ensured that the system achieved the desired parameters seamlessly. Understanding the significance of a reliable and cost-effective control board, I took it upon myself to design and soldered a dedicated stripboard. The implementation of this stripboard guaranteed enhanced reliability over a conventional breadboard setup, while also being a budget-friendly solution.