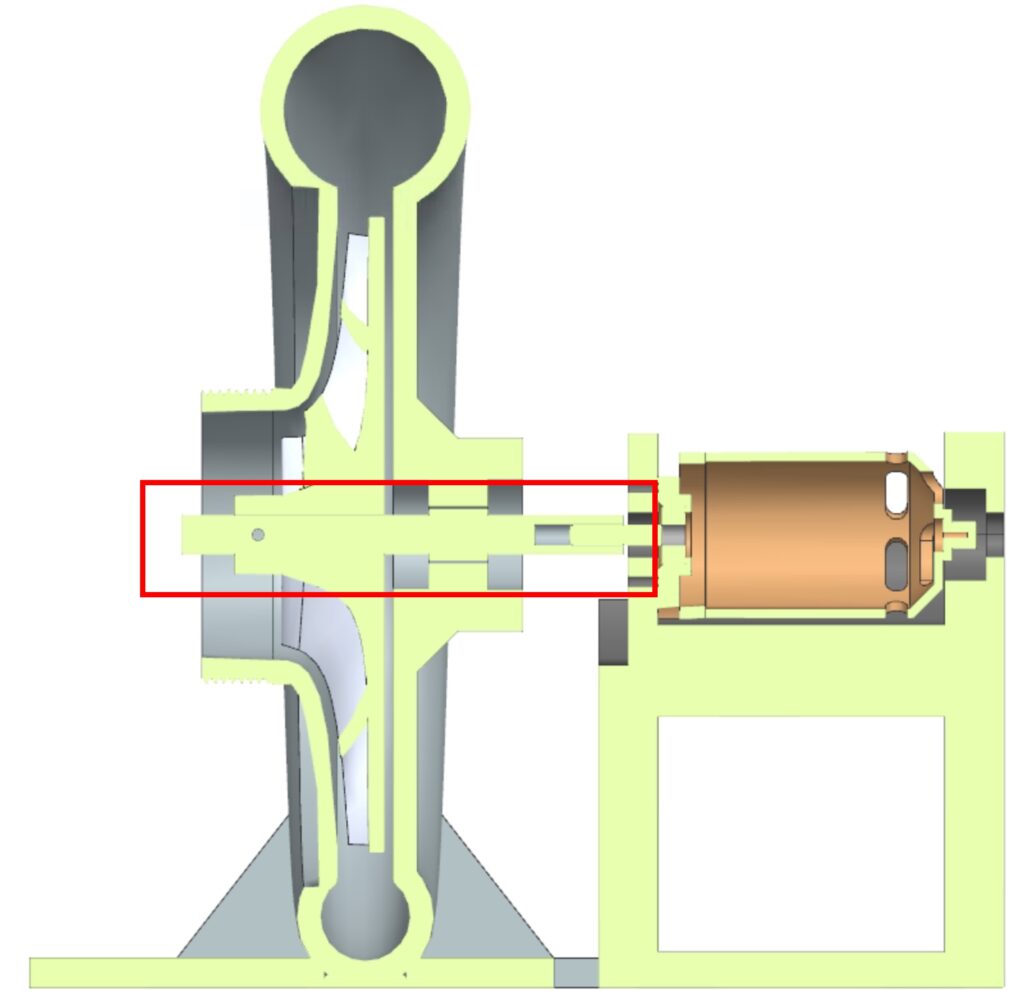

I am excited to share the details of our recent project focused on designing and manufacturing a prototype for a centrifugal vacuum pump. My objective was to develop a functional prototype that addresses key issues such as clearance optimization, shaft and support enhancement, motor and impeller coupling, volute sealing, inlet and outlet connections, and dynamic balancing.

In this project description, we will discuss the design and manufacturing process of the prototype, highlighting the key components and specifications.

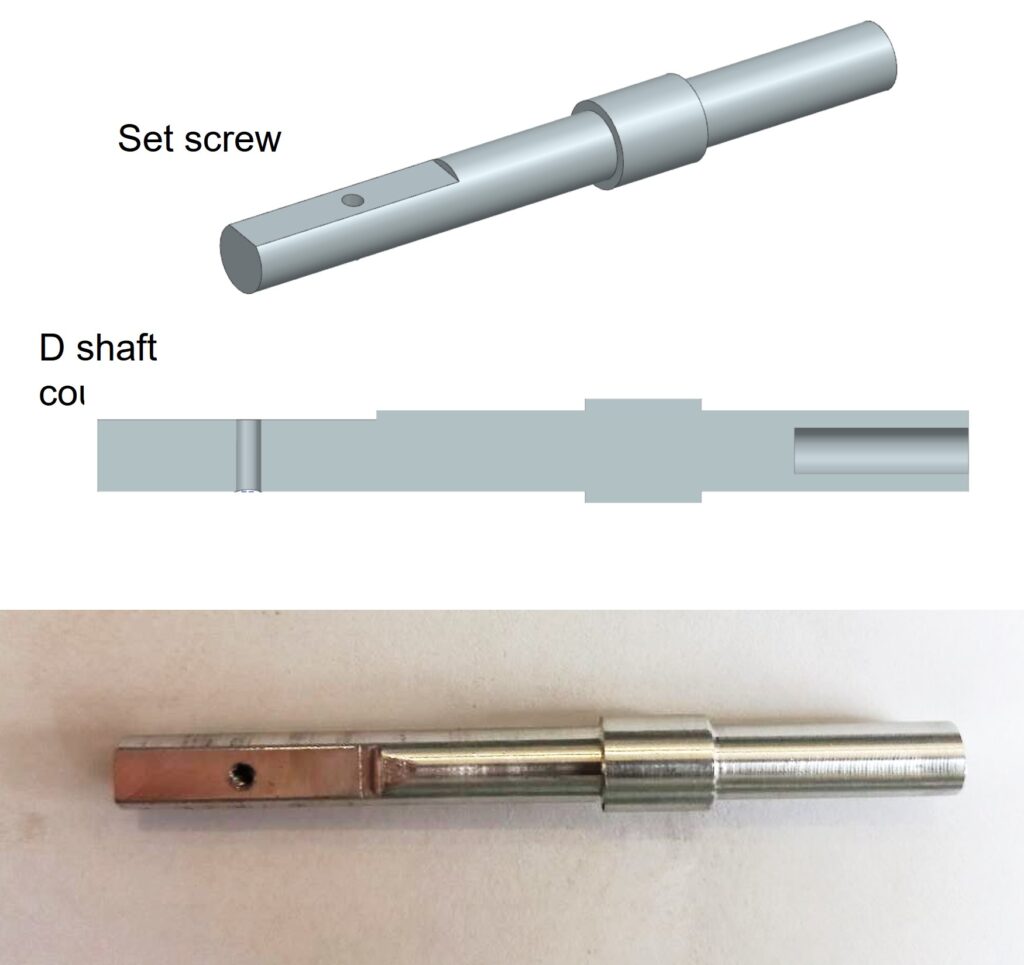

- Design and Component Selection: We meticulously designed the prototype, considering factors such as clearance optimization, shaft and support system, motor and impeller coupling, volute sealing, and inlet and outlet connections. Based on these considerations, we selected the QX-MOTOR 2600KV Brushless Motor (Model: QF2827-2600KV) and the appropriate shaft diameter of 4mm to ensure optimal power transmission and compatibility with the impeller.

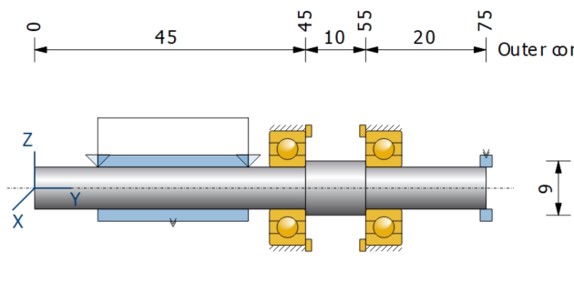

- Prototype Manufacturing: We proceeded with the manufacturing phase, which involved creating the necessary components for the centrifugal vacuum pump prototype. The prototype included an impeller, volute, shaft, bearings, and inlet/outlet connections. Deep groove bearings with a diameter of 7mm, outer diameter of 19mm, and width of 6mm were utilized to handle axial and radial loads.

- Testing and Evaluation: Once the prototype was manufactured, we conducted rigorous testing and evaluation to assess its performance and reliability. We measured key parameters such as speed, axial load, radial load, and torque to ensure optimal operation and efficiency. Additionally, we evaluated the effectiveness of the clearance optimization, shaft and support enhancement, volute sealing, and inlet and outlet connections.

Conclusion: Our centrifugal vacuum pump prototype successfully incorporated key optimizations to enhance efficiency and reliability. Through careful design, component selection, and manufacturing, we developed a functional prototype that addressed clearance issues, optimized the shaft and support system, ensured proper motor and impeller coupling, sealed the volute effectively, and optimized the inlet and outlet connections. The prototype underwent rigorous testing, demonstrating improved performance and reliability.

I am excited about the potential of this prototype and the foundation it provides for further development and optimization. If you have any questions or would like more information about our project, please feel free to contact me.